UNDERSTANDING ARC FLASHES

Today, we focus on Arc Flash Protection and the role of Personal Protective Equipment (PPE). With mounting industry awareness and the potential for extreme harm, it’s vital for every PCBU (Person Conducting a Business or Undertaking) to understand, assess and mitigate arc flash risk.

What is Arc Flash?

Arc flash is a dangerous electrical event caused by an unintentional discharge between phases or from a phase to earth. It produces intense light and heat—and in some cases, a destructive pressure wave known as an arc blast.

These events can happen in an instant and cause life-changing injuries.

Under the Health and Safety at Work Act (HSWA):

-

A PCBU must eliminate or, if not reasonably practicable, minimise risks

-

A documented arc flash risk assessment is essential

-

Mitigation steps should include PPE, procedural controls, and ongoing maintenance

Don’t leave arc flash risk unmanaged—it’s your legal and ethical responsibility.

Why Arc Flash Assessments Are Essential

In a recent project it was recommended through a Work Safe directed audit, that an arc flash study and report be compiled on a customer Motor Control Center (MCC). This was due to the necessity of personnel having to open panel doors, which exposed them to insulated bus assemblies, so they could isolate and or reset motor overloads or circuit breakers etc. The report presented an unacceptable high-risk arc flash hazard with an expected incident energy significantly higher than 40cal/cm². (calories per centimeter squared). This relates to an energy level that cannot be protected against with any PPE available.

Both the Customer and Athenry were shocked (excuse the pun) to discover that both the customer and Athenry staff have been subjected to this risk for such a long time. Thank God that there was never a fault!

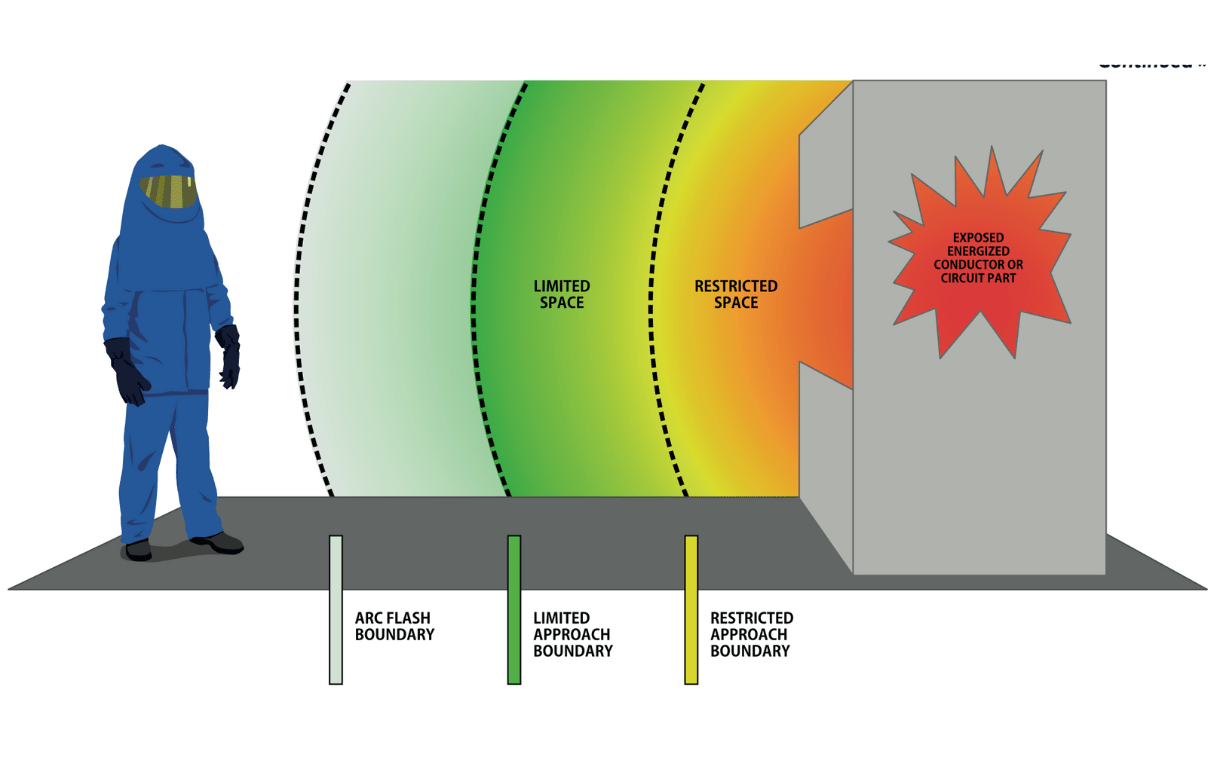

The report also described the arc flash boundary, which in this case was approximately 7 meters – Technically the distance from live parts that are uninsulated or exposed with which a person could receive second degree burns if an arc flash was to occur – this is the closest anyone may approach without the use of PPE.

The report recommended:

- Replace the incomer ACB with a new intelligent ACB which provides network capabilities and add a remote-control panel for applying Energy Reduction Maintenance settings and remote trip reset functions

- Lockable doors with extended rotary handles on circuit breakers/starters etc.

- Install arc flash hazard labels in MCC room to identify Arc Flash hazard risk

With the risk and potential consequences identified Athenry worked with the customer and assisted with implementing mandatory minimum PPE requirements, Standard Operating Process for access to MCC room, guidance for wearing and maintaining PPE and worked toward upgrading MCC as per recommendations of the report.

High-Risk Arc Flash Hazard Identified

As part of our commitment to maintaining the highest standards of electrical safety, Athenry Electrical has robust isolation and Lock Out Tag Out (LOTO) procedures. This update covers access and work around Low Voltage Electrical Switchboards, Switch Rooms, and Motor Control Centres (MCCs), including isolation, resetting, testing, and terminations.

With this isolation approach, unless a current, documented risk assessment and maintenance schedule exists—particularly for larger MCBs and ACBs—our Electricians will conduct their own Safe Work Method Statement (SWMS) or Job Safety Analysis (JSA) prior to beginning any work. This ensures hazards are identified and appropriate PPE and control measures are implemented.

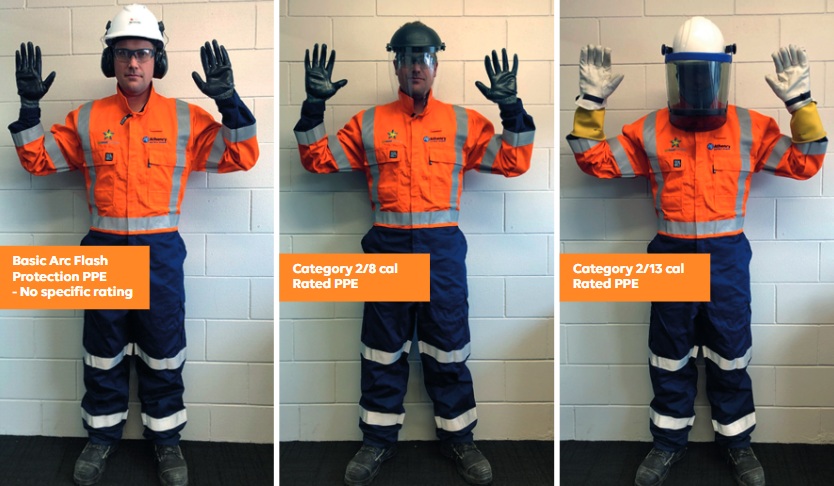

All Athenry staff are now equipped with:

- Arc-rated overalls (Class 2 / 8 cal/cm²)

- Electrical safety gloves

- Face shields

This PPE is the minimum standard for all switchboard-type work and complies with AS/NZS 4836. If higher risk is identified—such as elevated arc flash potential—our team will escalate accordingly. This may involve total isolation, rescue-trained personnel, or a specialist Arc Flash Risk Assessment.

Our stance is clear: Safety will never be compromised due to operational pressures.

We remind all plant owners that it is your responsibility under the HSWA to ensure risks are known, maintenance is up to date and appropriate signage is visible. However, Athenry is here to support you through this process.

Many older circuit breakers and switches have never been tested or maintained and pose serious risks including malfunction, internal failure or arc flash. Even when functional, these aging devices may not isolate or reset properly—leading to dangerous conditions and costly downtime.

We strongly recommend conducting a full review of your power distribution and circuit protection systems. With this knowledge, a Standard Operating Procedure (SOP) can be established to guide safe access, testing and isolation practices.

If you’re unsure where to start, we’re here to help.

You May Also Like…

Process Matters

Safety is non-negotiable—any unsafe act or condition must be reported and corrected immediately.

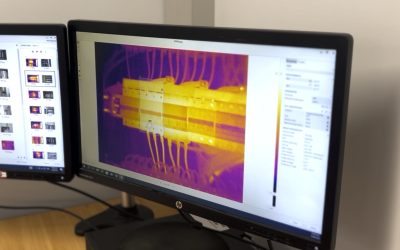

Thermal Imaging Puts The Heat On Insurance Premiums

Protect your plant with our certified thermal imaging service—accurate, preventative, and fully compliant.

Machine Safety Requirements Process

Machine safety is built into everything we do—protecting workers, equipment, and compliance.