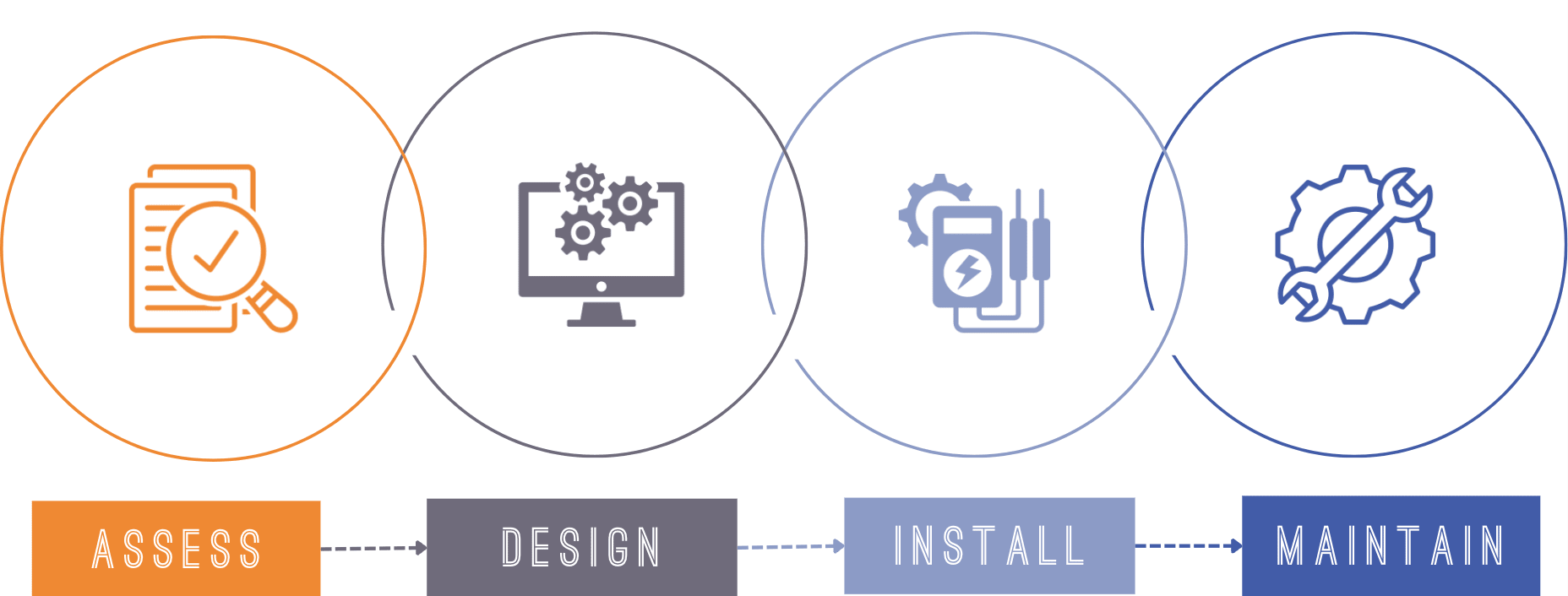

Our process

OUR PROCESS

By conducting a thorough initial assessment, in consultation with the customer, the design process can proceed with a clear understanding of the project's requirements and constraints, leading to a safe, efficient and compliant electrical installation.

Our engineers design your tailored electrical installation, ensuring it aligns with safety regulations and all relevant codes. The design is reviewed for safety and efficiency, and necessary approvals from the customer are obtained before proceeding with the installation.

Our skilled electricians bring your electrical design to life with safe, reliable and compliant installations. We conduct thorough testing, inspections and final commissioning to meet all standards and ensure operational readiness.

Our 24/7 maintenance and call out services enhance the safety and efficiency of your electrical installations. Our services include routine inspections, preventive maintenance and corrective actions to prevent failures, reduce operational costs and minimize downtime.

ASSESSMENT

The initial assessment of any electrical installation before designing requires several key steps to ensure that the design process is well-informed and aligned with the project’s requirements, leading to a safe, efficient and compliant electrical installation. These steps include:

Site Survey

- Conduct a thorough physical inspection of the site in consultaion with the customer.

- Document existing electrical infrastructure and any constraints or challenges.

- Assess environmental factors (e.g., temperature, humidity, exposure to elements) that could impact the installation.

System Integration

- Consider how the new installation will integrate with existing systems and infrastructure.

- Assess compatibility with other electrical and mechanical systems.

Documentation

- Compile all relevant data, including site survey results, load analysis and regulatory requirements.

- Prepare preliminary sketches and diagrams as necessary.

Load Analysis

- Determine the total electrical load requirements, including peak and average loads.

- Identify critical and non-critical loads.

- Consider potential future load increases and expansion needs.

Energy Efficiency

- Evaluate opportunities for incorporating energy-efficient technologies and practices.

- Consider renewable energy sources and sustainable design principles.

Budget

- Estimate the initial costs for materials, labour and additional expenses.

- Consider long-term operational and maintenance costs.

power Supply Assessment

- Evaluate the existing power supply and its capacity to meet the anticipated load.

- Identify any necessary upgrades or changes to the power supply infrastructure.

Safety Considerations

- Identify potential safety hazards (e.g., risk of electrical shock, fire hazards).

- Plan for safety measures such as proper grounding, circuit protection and emergency shut-off mechanisms.

Stakeholder Consultation

- Identify the purpose and scope of the electrical installation.

- Engage with all relevant stakeholders (e.g., clients, architects, contractors) to gather detailed information regarding their specific needs and expectations, and ensure alignment with project goals.

DESIGN

Once a thorough assessment of an electrical installation is completed, the design process can proceed with greater clarity and precision. The following steps ensure the design meets all project requirements, safety standards and regulatory guidelines.

Preliminary Designs

- Create initial design sketches and layouts based on the assessment findings.

- Consider different design options and approaches to meet the project requirements.

Component Selection

- Select appropriate electrical components, including circuit breakers, switches, conduits and fixtures.

- Ensure components meet quality standards and regulatory requirements.

Lighting Design

- Plan the lighting layout, including the placement of fixtures, controls and emergency lighting.

- Incorporate energy-efficient lighting solutions.

Emergency Power

- Design backup power systems, such as generators or UPS (Uninterruptible Power Supply), to ensure continuity during power outages.

- Plan for emergency shut-off mechanisms and safety protocols.

Cost Estimation

- Develop a detailed cost estimate based on the finalised design.

- Align the design with the project budget and identify cost-saving opportunities.

Detailed Load Calculation

- Perform detailed load calculations to determine the exact power requirements for various components and systems.

- Size conductors, transformers, panels and other equipment appropriately.

Cable Routing and Layout

- Plan the routing of cables, conduits and wiring paths throughout the installation.

- Optimise cable paths for efficiency and minimise interference.

Safety Systems Design

- Integrate safety systems such as grounding, bonding, surge protection and fire detection.

- Ensure compliance with safety codes and standards.

Energy Management

- Integrate energy management systems to monitor and optimize energy consumption.

- Consider incorporating renewable energy sources and storage solutions.

Review and Approval

- Conduct a thorough review of the design with all stakeholders.

- Make necessary revisions based on feedback and obtain approval from relevant authorities.

Schematic Diagrams

- Develop detailed electrical schematics showing the interconnections of all components.

- Include circuit diagrams, panel schedules, and distribution layouts.

Power Distribution Design

- Design the power distribution system, including main distribution boards, sub-panels and feeder circuits.

- Ensure balanced load distribution across phases.

Control Systems Design

- Design control systems for managing and monitoring the electrical installation.

- Include provisions for automation, if applicable.

Documentation

- Prepare comprehensive documentation, including detailed drawings, specifications and installation instructions.

- Include material lists, equipment specifications and testing protocols.

Implementation Plan

- Develop a detailed implementation plan outlining the steps for installation, testing and commissioning.

- Include timelines, resource allocation and project management strategies.

INSTALLATION

Once the assessment and design process has been completed and accepted by all stakeholders, the implementation of the electrical design can be carried out. To ensure a safe, reliable and compliant electrical installation that meets the project’s goals, we follow the below steps.

Project Planning

- Develop a detailed project plan outlining timelines, milestones and deliverables.

- Allocate resources, including personnel, equipment and materials.

- Establish clear communication channels among all team members and stakeholders.

Installation

- Begin the installation process following the design plans and schematics.

- Install conduits, wiring, panels, transformers, switches and other electrical components.

- Ensure that installations are performed by qualified electricians and adhere to safety and regulatory standards.

Training and Handover

- Provide training for end-users.

- Ensure a smooth handover of the system, including all relevant documentation and operational guidelines.

Procurement

- Order and acquire all necessary materials and equipment as per the design specifications.

- Ensure timely delivery of materials to the site to avoid project delays.

Quality Control

- Conduct regular quality checks and inspections throughout the installation process.

- Verify that all work meets design specifications and regulatory requirements.

- Address any issues or discrepancies promptly to maintain project quality.

Certification

- Arrange for a final inspection by relevant authorities to obtain necessary certifications and approvals.

- Ensure that all regulatory and safety requirements are met.

Site Preparation

- Prepare the site for installation, including clearing the area and setting up temporary facilities if needed.

- Ensure all safety measures are in place, such as proper signage, barriers and personal protective equipment (PPE).

Testing and Commissioning

- Perform thorough testing of all installed systems to ensure they function correctly and safely.

- Conduct tests such as continuity tests, insulation resistance tests and load tests.

- Commission the electrical system, verifying its performance under normal operating conditions.

Documentation

- Compile comprehensive documentation, including as-built drawings, test reports and equipment manuals.

- Maintain accurate records for future reference and maintenance purposes.

MAINTENANCE

By implementing comprehensive maintenance services, industrial facilities can enhance the reliability, safety, and efficiency of their electrical installations, ultimately reducing operational costs and minimizing downtime.

Preventive Maintenance

- Regular Inspections: Schedule routine inspections to check for signs of wear, corrosion and other potential issues.

- Cleaning and Lubrication: Clean electrical components and apply lubrication to moving parts to prevent deterioration and ensure smooth operation.

- Tightening Connections: Ensure all electrical connections are secure to prevent loose connections that could lead to arcing or overheating.

- Testing and Calibration: Perform regular testing of protective devices, such as circuit breakers and relays and calibrate them to ensure proper operation.

Safety Checks & Compliance

- Grounding and Bonding Inspections: Ensure proper grounding and bonding of electrical systems to prevent electrical shock and ensure safe operation.

- Arc Flash Analysis: Conduct arc flash studies and implement necessary protective measures to safeguard personnel from arc flash hazards.

- Regulatory Compliance: Ensure that all maintenance activities comply with local, national and international electrical codes and standards.

Predictive Maintenance

- Thermographic Inspections: Use infrared thermography to identify hot spots and potential failure points in electrical systems.

- Vibration Analysis: Monitor vibrations in electrical motors and other equipment to detect imbalances, misalignments or bearing failures.

- Oil Analysis: Test the dielectric oil in transformers and other oil-filled equipment to detect contaminants and assess the condition of the oil.

Documentation

- Maintenance Logs: Maintain detailed logs of all maintenance activities, including inspections, tests, repairs and replacements.

- Service Reports: Provide comprehensive service reports outlining the condition of the electrical system and any actions taken.

- Maintenance Schedules: Develop and adhere to maintenance schedules to ensure timely execution of all maintenance tasks.

Corrective Maintenance

- Troubleshooting and Repairs: Diagnose and repair faults in the electrical system promptly to restore normal operation.

- Component Replacement: Replace worn-out or damaged components, such as fuses, circuit breakers and wiring, to prevent system failures.

- System Upgrades: Implement upgrades to improve system performance, enhance safety or comply with updated standards and regulations.

24/7 Support

- 24/7 Support: Provide around-the-clock support to address any electrical emergencies promptly.

- Rapid Response: Have a dedicated team ready to respond quickly to electrical faults, minimizing downtime and ensuring safety.