MACHINE SAFETY

At Athenry Electrical, we understand that the safety of your employees is paramount. When it comes to industrial machinery, even minor malfunctions can lead to serious injuries. That’s why we offer comprehensive machine safety solutions to create a secure working environment for your team.

Our team of electrical engineers works collaboratively to implement a multi-layered approach to machine safety:

- Risk Assessments and Hazard Identification: We conduct thorough risk assessments to identify potential hazards associated with your machinery, considering factors like moving parts, electrical risks and pinch points.

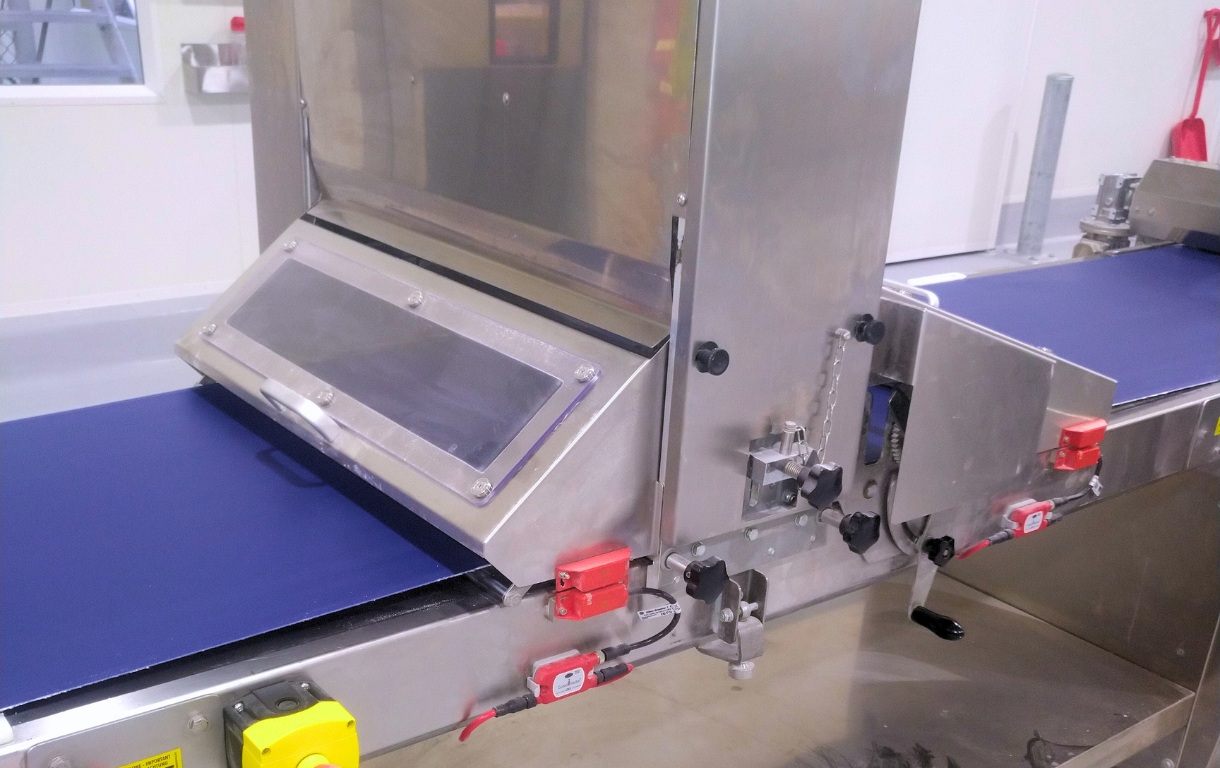

- Safety Guarding and Interlocking Systems: Our team designs and installs appropriate safety guards, such as light curtains, safety gates and interlocks, to prevent accidental contact with hazardous areas.

- Machine Control System Integration: We integrate safety protocols into your machine control systems, ensuring equipment stops automatically in case of malfunctions or safety breaches.

- Operator Training and Awareness Programs: We provide comprehensive training programs for your operators on safe machine operation procedures and proper hazard identification.

- Compliance with Safety Regulations: We ensure your machinery adheres to all relevant safety regulations and standards, including those set by the Australian Standard AS 4024 Safety of Machinery series and relevant industry bodies.

- Ongoing Maintenance and Inspection: We offer ongoing maintenance and inspection services to identify and address potential safety issues before they arise.

The Machine Risk Assessment (MRA), Safety Requirement Specification (SRS) and Safety Validation are all critical parts of complying with the requirements laid out in the Health and Safety at Work Act. Athenry can undertake and organise the MRA and SRS for the client if required.

Machine Risk Assessment (MRA)

An MRA document is to be provided by the client to show a complete risk assessment of the machine or system. The MRA will give a risk score once completed to advise on likelihood, risk and severity of potential injury. The MRA score will be used to develop the Safety Requirement Specification (SRS) document to which the machine or system will be designed to mitigate the risk. Athenry can undertake and organise the MRA for the client if required.

Safety Requirement Specification (SRS)

An SRS is a document provided by the client upon requirement for safety validation of envisaged works or an existing system. An SRS document is prepared to specify and define what is required from Athenry to undertake safety validation.

The intention of an SRS document is to present the information required for the design of the safety system as clearly, completely and accurately as possible so that design of the safety system will meet the functional safety requirements, and the required level of risk reduction is achieved.

The machine owner / operator is responsible for the SRS, Athenry can undertake and organise the SRS for the client if required.

Safety Validation Documentation

A complete validation can be completed by Athenry. The validation document will encompass all the safety related documentation into the one document. It will be specific to the project and require thorough overview of the safety system. It will also include recordings of testing and specific material information as well as the signing off from the certified safety expert to show satisfactory completion of validation.

In detail the validation document will provide the following:

- An Introduction into the project

- All general information about the project

- The objective of the safety validation

- The complete validation processes

- All validation principles explained in detail

- A fault list explaining all potential faults

- The validation plans

- Validation record

- Compliance requirements of the safety system to meet the specified safety performance level

- An overview of the safety system

- Safety principals

- Well-tried safety principals and components

- A list of fault exclusions

- A component validation for all Electrical equipment

- Function overview

We choose safety and take Health & Safety seriously

Get In Touch

SUBSCRIBE TO OUR NEWSLETTER

To receive the latest industry news and insights and our new Athenry Electrical Knowledge Series